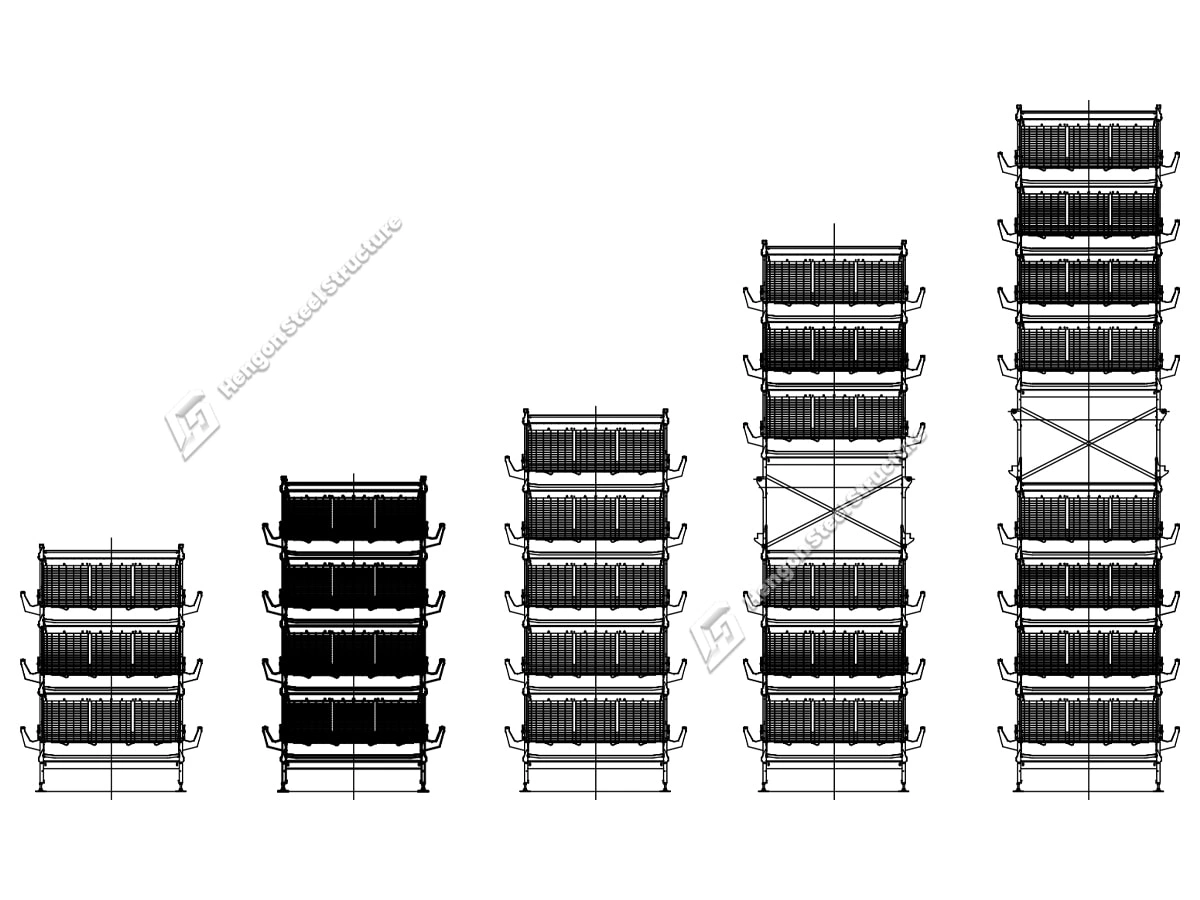

| Type | Heignt(mm) | Width(mm) | Depth(mm) | Bottom Mesh(cm²) | Total Height(mm) |

| 9HLXy4384A | 640 | 1250 | 650 | 8125 | 2890 |

| 9HLXy5480 | 640 | 1250 | 650 | 8125 | 3530 |

| Double-deck | Double-deckplatform and fence aisle | ||||

| 9HLXy8768 | 640 | 1520 | 650 | 8125 | 6265 |

The traveling feeding system ensures even feed distribution. The hopper features a special adjustment mechanism that allows feed volume to be modified as birds grow.

The trough is made of hot-dip galvanized sheet and equipped with an internal adjustment plate. Chicks feed from below the plate in early days, and as they grow, the plate drops, allowing access from above. An anti-escape wire above the plate prevents chicks from jumping out. This smart combination ensures free feeding while keeping chicks safely in place.

Cage Mesh: The bottom mesh uses imported galfan wire, high strength, good elasticity, and smooth surface. It effectively reduces bird fatigue and minimizes eggshell damage.

Steel Sheet: Made of 275g zinc-aluminum-magnesium coated steel, customized for high strength and excellent corrosion resistance, ensuring long-term durability.

Column spacing: 1250 mm. Short span with multiple support points ensures excellent equipment stability.

Easy-to-operate cage doors help reduce feed waste caused by bird movement.

Lock-type sliding doors and spring-loaded inward-push doors for secure and convenient access

Imported nipple drinkers with V-shaped drip troughs beneath the water lines prevent water from dripping onto the manure belt.

Deep V-shaped feed trough ensures feed distribution. Feed is automatically collected within the optimal feeding zone, preventing mold and ensuring birds always access fresh feed, reducing waste.

Fully digitized robotic processing with 11-step bending for high strength—strong enough to withstand foot traffic. Plug-in connections provide enhanced stability.

Seamless rail-to-trough connection with smooth-running guide wheels ensures quiet, stable operation and uniform feed delivery.

Made from internationally branded raw materials, the PP manure belt uses 100% virgin material for durability and safety.

High overall processing precision, with connection tolerance within 1 mm, ensures smooth and consistent belt operation.

Built-in double scrapers ensure thorough manure removal.

Unified open/close mechanism with removable scrapers for easy cleaning and replacement.

Stainless steel pull rods and scraper components for longlasting performance.