In today's construction industry, prefab steel structures are the top choice for industrial and commercial projects worldwide. Hengon is a trusted steel building manufacturer in China.

We recently shipped a large steel structure project to the United States. This project is for a cement plant facility. This delivery shows our skill in making structural steel. It also shows our ability to offer custom solutions that meet top international standards.

Project Overview: U.S. Cement Plant with Office Space

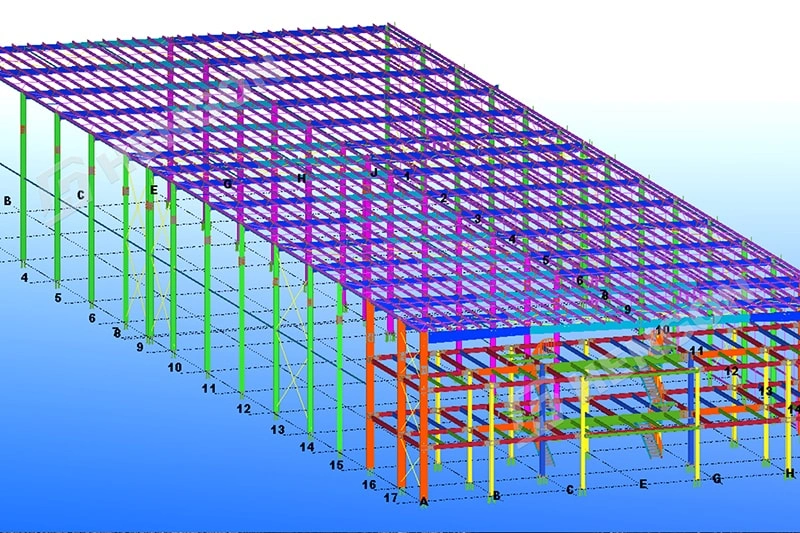

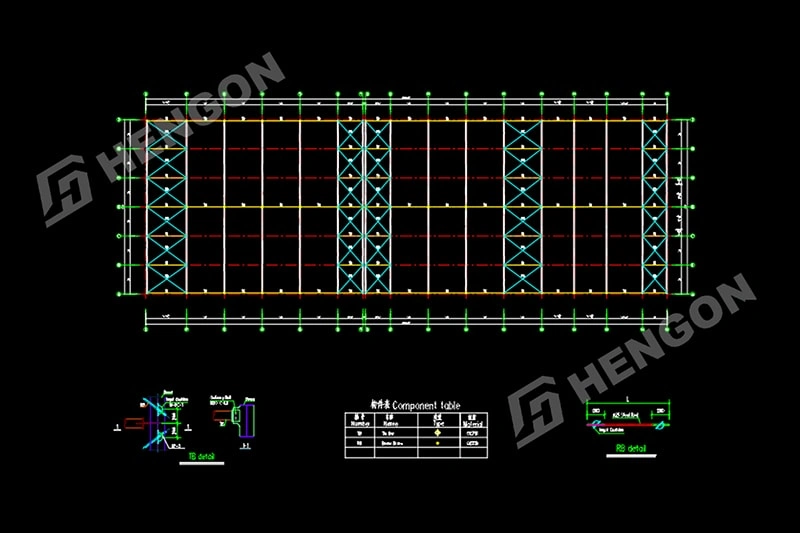

The project is 358 feet long, 120 feet wide, and 13.5 feet high. It includes a three-floor mezzanine office. This office supports the cement plant's administrative and operational needs through its design.

This mix of factory buildings and office space shows modern manufacturing. It combines function and efficiency in one design.

Our client’s design team made the first drawings. Hengon’s skilled engineers worked closely with them to finish the design details. Once the client’s architect stamped approval, we began structural steel fabrication and production for the cement plant project.

Quality Materials and Engineering Precision

At Hengon, quality always comes first. For this cement plant project, the building materials included:

Roof Panels: 0.8mm steel sheet with 100mm glass wool insulation for durability and thermal efficiency.

Wall Panels: 0.7mm color-coated steel panels for strength and modern aesthetics.

Structural Coating: The whole steel frame was coated with epoxy paint. This provides long-lasting protection against rust, moisture, and wear from industry.

Before finalizing the order, we shipped material samples to the client for review. This extra step built trust in the chosen materials. It also showed Hengon’s commitment to being open and satisfying customers.

Shipment and Global Delivery

The design was approved, and production was finished. The team packed and shipped the prefabricated steel parts to the U.S. cement plant site. Hengon has many years of experience exporting steel structures to America, Africa, and Asia. They make sure every delivery is safe, efficient, and meets local standards.

This shipment shows how we serve global clients in the metal building industry. We handle everything from factory buildings to manufacturing buildings and more.

Why Pre-Engineered Steel Structures for Cement Plants?

Compared with traditional concrete construction, prefab steel structures provide significant advantages:

Faster Construction – Prefabricated components are manufactured off-site, reducing on-site labor and delays.

Cost-Effective – Lower material waste and predictable budgets make steel buildings more economical.

Durability – With advanced coatings like epoxy, steel structures withstand harsh industrial environments.

Flexibility – Easily adaptable to future expansions or design changes.

For heavy-duty projects such as cement plants, these advantages make steel the ideal solution.

Why Choose Hengon?

Hengon stands out among global steel building manufacturers and structural steel fabricators for several reasons:

15+ Years of Experience in international projects.

One-Stop Service: design, fabrication, shipment, and installation.

Customized Solutions for factory buildings, warehouses, poultry houses, and large-scale industrial projects.

Strong Global Presence with successful projects in 20+ countries, including the U.S., Africa, and Southeast Asia.

Proven Expertise in structural steel fabrication for complex industrial facilities.

Conclusion

The delivery of this prefab steel structure for a cement plant to the United States was successful. This demonstrates Hengon’s leadership in the metal building industry. From manufacturing buildings to factory buildings and large industrial plants, Hengon continues to deliver precision engineering, durable steel structures, and reliable service worldwide.

If you need trusted partners for steel structures in America or other areas, Hengon is a reliable choice.