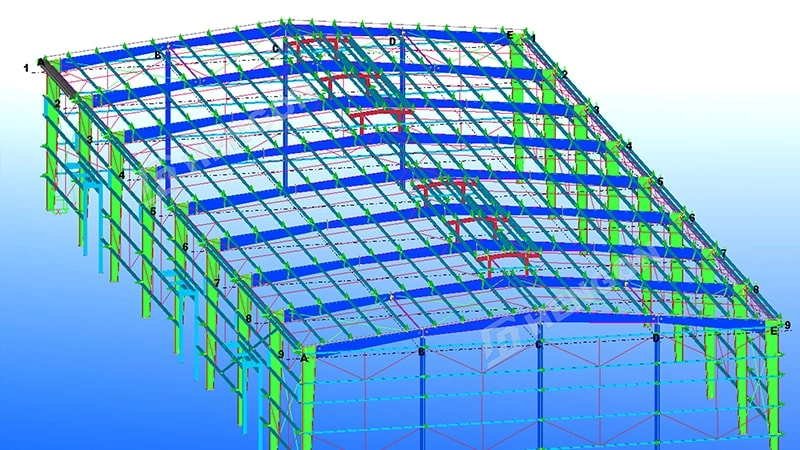

--Optimized column distance to be 7.5m, saving overall cost

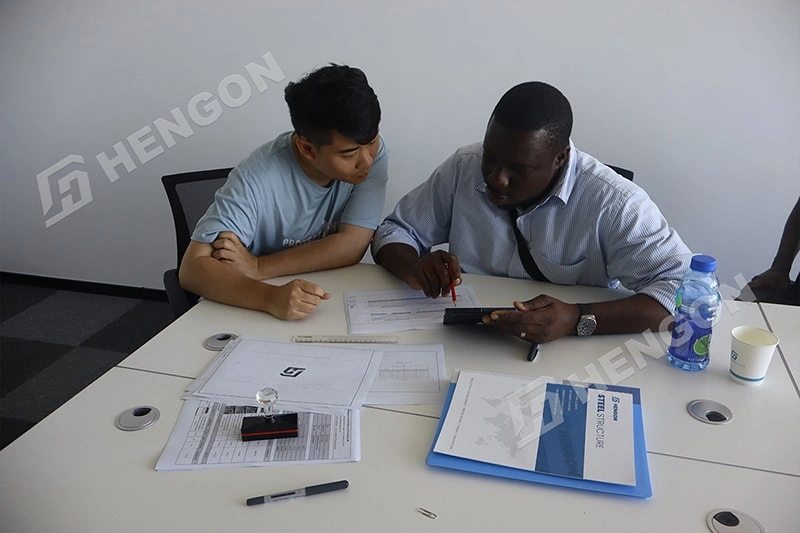

A professional engineering client visited Hengon to finalize the technical design of their upcoming steel structure project.

| Tanzania workshop --Optimized column distance to be 7.5m, saving overall cost | |||||

| Country | Tanzania | Year | 2025 | ||

| Project Information | |||||

| Project | Steel production workshop | Dimension | 60m×25m×8m | Gutter | PPGI(pre-painted galvanzied iron) 0.6mm |

| Material | Q355B steel | Paint | Alkyd paint | Purline | C purline |

| Roofing and wall | Corrugated single sheet 0.4mm Corrugated cladding wall sheet 0.4mm | Door | Electricity rolling shutter door | ||

During the meeting, several key design improvements were proposed and refined, resulting in a more efficient and cost-effective solution.

During the technical discussion at our office, the client requested to increase the column spacing from 6m to 7.5m to better suit their functional and layout requirements.

Our engineering team immediately reviewed the structural loads, recalculated the framing system, and updated the full design on-site.

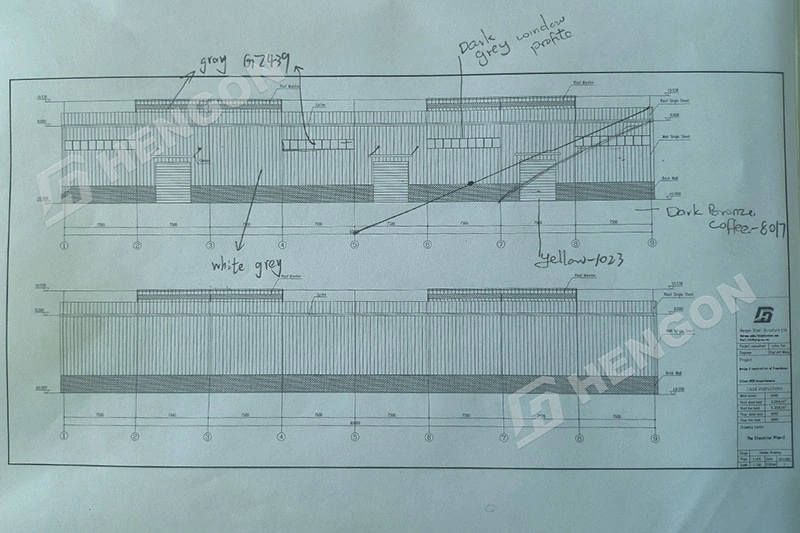

After touring our new manufacturing facility, the client was impressed by the clean architectural style and selected the same modern green color for their building.

This color has a high visual impact and reflects a professional, modern industrial image.

Because this is the client’s first factory, visual appearance was very important. They requested a customized exterior color combination to match their brand identity and create a standout, aesthetically pleasing facility.

This project highlights Hengon’s ability to respond quickly to engineering changes, provide professional design optimization, and deliver highly customized aesthetic solutions.

From structural adjustments to visual design support, our goal is to help clients build a factory that is functional, cost-efficient, and visually impressive.