Introduction: The Evolution of Modern Construction

Global construction is changing. Moving towards faster, greener, and cheaper solutions.

Pre-Engineered Buildings (PEB) are now important for modern infrastructure. Today’s PEB systems are not just for traditional industrial sheds. They now support commercial projects, public facilities, logistics hubs, residential buildings, and large urban developments. This article explores why PEB has become the preferred building solution for forward-thinking developers, architects, and contractors worldwide.

What Is a Pre-Engineered Building (PEB)?

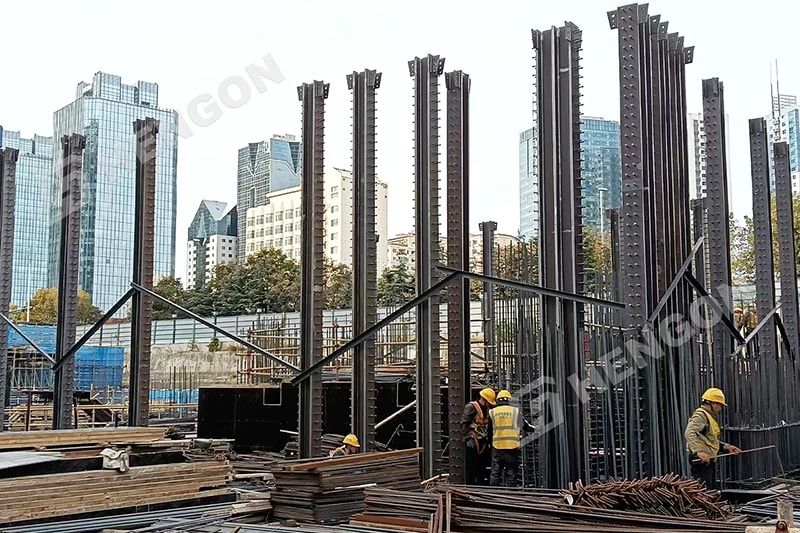

A Pre-Engineered Building is a system that designers fully design and manufacturers make in a factory. They then deliver it to the site for assembly. Using standard parts like beams, columns, bracing, and roof or wall panels, PEB ensures accuracy. This method also reduces material waste and speeds up construction.

In simple terms, a PEB is like assembling a high-strength structural “kit,” engineered for maximum efficiency and durability.

Rapid Construction with High Precision

One of the greatest advantages of PEB is speed.

Because the team manufactures all major components in advance, on-site work remains limited to assembly. This reduces construction time by 30–50%, minimizes weather-related delays, and ensures consistent quality throughout the process.

Factory-controlled production also means tighter tolerances and fewer installation errors, resulting in a more reliable long-term structure.

Cost Efficiency Without Compromise

PEB systems optimize material usage and streamline fabrication, making them significantly more economical than conventional construction. Developers benefit from:

Reduced steel consumption

Lower labor and installation costs

Shorter overall project timelines

Reduced rework and waste

This combination delivers a higher return on investment without compromising structural strength or safety.

Sustainability and Green Building Advantages

Sustainability is a defining factor for modern infrastructure, and PEB naturally aligns with green-building principles:

Steel materials are recyclable

Factory-controlled production reduces waste

Components can be dismantled, reused, or relocated

Designs can integrate solar panels and energy-saving systems

Improved thermal performance lowers operational costs

These features make PEB a future-ready solution for industries seeking eco-friendly development.

Structural Strength and Design Flexibility

Despite their efficiency, PEB structures deliver exceptional performance:

Engineered to withstand heavy wind, snow, and seismic loads

Capable of achieving large clear spans

Adaptable for mezzanines, cranes, façades, and architectural enhancements

Suitable for both simple warehouses and complex commercial facilities

Modern PEB designs offer freedom comparable to, and often exceeding, traditional construction methods.

Low Maintenance and Long-Term Durability

Because PEB components are precisely fabricated and often coated for corrosion protection, the buildings require minimal maintenance throughout their lifecycle. High-quality steel combined with optimized engineering ensures longevity, making PEB ideal for long-term industrial, commercial, and infrastructure applications.

Applications Across Multiple Sectors

PEB structures are widely used across sectors including:

Industrial: factories, logistics centers, cold storage

Commercial: malls, showrooms, office buildings

Institutional: schools, auditoriums, training centers

Infrastructure: airports, metro stations, transit hubs

Residential: prefab homes, villas, farmhouses

The adaptability of PEB enables seamless customization for different project needs.

Technology Driving the Future of PEB

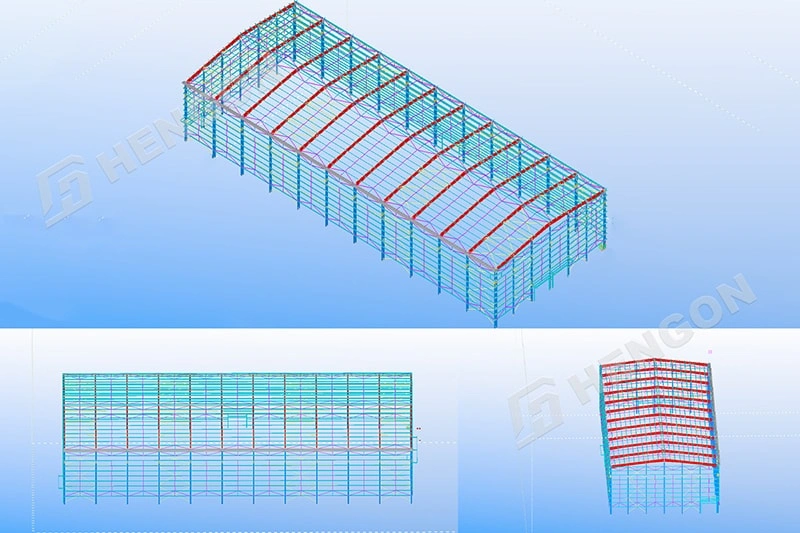

Modern PEB systems integrate advanced construction technologies:

BIM (Building Information Modeling) for digital accuracy

CNC automated steel fabrication for precision

Pre-assembly checks to ensure zero on-site errors

Compatibility with smart building solutions

These technologies ensure quality, efficiency, and long-term value.

Conclusion: Building Smarter for the Future

PEB structures mark a new era in construction. They combine speed, sustainability, and long-lasting durability in one solution. As more industries move to prefabricated, high-efficiency building methods, PEB systems will stay important for global infrastructure development.

For developers, architects, and investors who want to build better and quicker, PEB is not just an option. It is the future of construction.