1. Optimized Geometric Design: Structure Shapes Performance

The shape of a poultry house—its length, width, height, and roof angle—affects how well it ventilates. It also impacts the indoor climate and energy use. A scientifically designed building envelope ensures proper air mixing, smooth airflow organization, and temperature uniformity.

Different climates require different eave–cage height spacing:

- Cold / high-latitude regions (Europe, Canada, Russia): A minimum 1.2–1.4m We need a gap between the eave and the cage top. This helps prevent cold drafts and ensures good air mixing before it enters the bird area.

- In hot places like Southeast Asia, the Middle East, and Africa, a space of at least 0.6 meters is usually enough. This spacing helps increase airflow and cooling.

Roof pitch also plays a critical role:

- Standard designs: 10%–15% slope for balanced drainage and insulation.

- Heavy rainfall or snow regions: 20%–50% to improve water shedding capability.

A well-designed geometry leads to:

- More stable airflow

- More uniform temperatures

- Lower operational energy cost

- Better long-term durability

2. Airtightness & Insulation: The Foundation of Environmental Control

A high-performance poultry house begins with excellent airtightness. A properly sealed house allows precise temperature and ventilation control, supporting both animal welfare and production efficiency.

Industry airtightness guideline: When you close all inlets, 5 air changes per hour. This should create a negative pressure of 30 to 35 Pa.Meeting this standard indicates a well-sealed building.

High insulation (high R-value) wall and roof materials further reduce temperature fluctuations and energy consumption. Smooth wall surfaces also minimize dust accumulation and support hygiene protocols.

Benefits of airtightness + insulation:

- Precise temperature management

- Better performance in both hot and cold seasons

- Improved egg production or growth rate

- Significantly reduced energy bills

3. High-Efficiency Ventilation: The Core Technology of Modern Poultry Houses

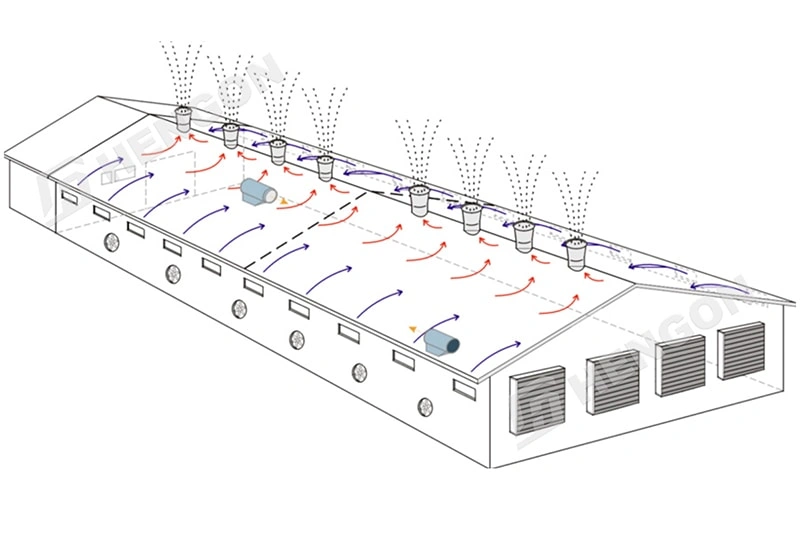

Ventilation is the most critical system in any modern poultry house. Different ventilation modes suit different climates, building types, and production scales.

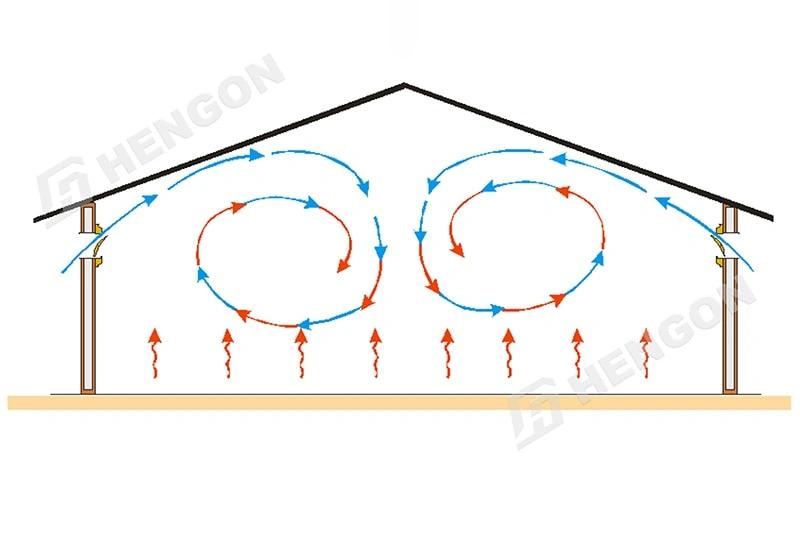

Common Ventilation Modes:

- Aisle Ventilation: Aisle wind speed 3–5 m/s, cage area 0.3 m/s.

- Over-Cage Ventilation: Cage wind speed can reach 0.5–1.5 m/s, offering superior heat mixing.

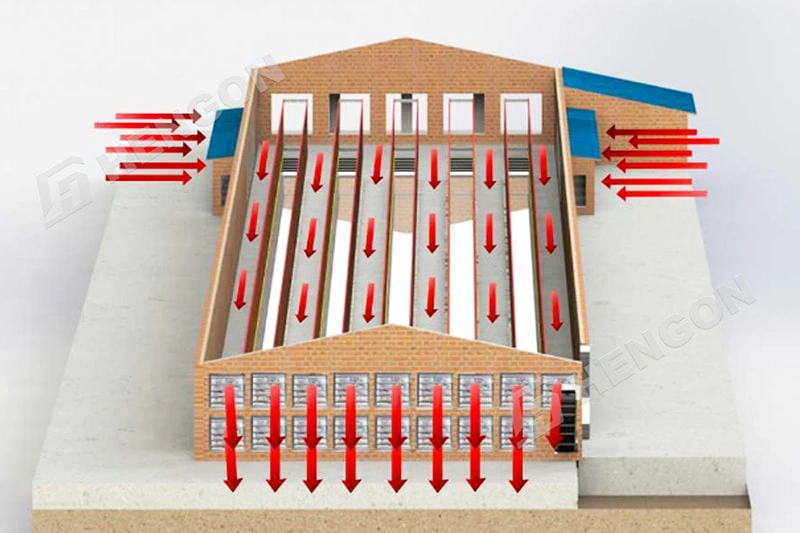

- Lateral Ventilation: Suitable for mild climates, prioritizes fresh air exchange.

- Tunnel Ventilation: High wind speed for strong wind-chill effect, ideal for hot climates.

- Hybrid (Combined) Systems: Used in regions with extreme seasonal differences.

Wind Speed Requirements: When temperatures exceed 26°C, you need a wind speed of 2.0 m/s. This helps a 2 kg bird avoid heat stress.

Benefits of efficient ventilation:

- Removes body heat

- Provides oxygen and fresh air

- Controls humidity and ammonia

- Keeps temperature difference front-to-back < 2°C

Proper ventilation = fewer losses + better growth + improved FCR.

4. Cooling Systems: Ensuring Safe Thermal Conditions in Hot Climates

In tropical and subtropical regions, evaporative cooling pads combined with tunnel ventilation are the most common and effective solution.

1. Evaporative Cooling Pads

- Suitable for hot, moderate-humidity climates

- Installed inside the ante-room for greater winter insulation

- Adjustable flaps help optimize airflow direction

2. Wind-Chill Cooling Effect

When humidity is high and cooling pads are less effective, increasing wind speed can still help cool birds down. A wind speed of 2 m/s effectively reduces perceived temperature even if the dry-bulb temperature doesn’t change.

3. Cooling Strategy Recommendations

- Below 32°C: use wind cooling, energy-saving mode

- Above 32°C: activate cooling pads for evaporative cooling

- High-humidity regions: avoid full-house fogging systems

Correct cooling strategy protects birds from heat stress and stabilizes production performance.

5. Smart Control & Energy Efficiency: The Future of Poultry Farming

The true value of a modern poultry house lies not only in the building itself but also in the precision of its management systems.

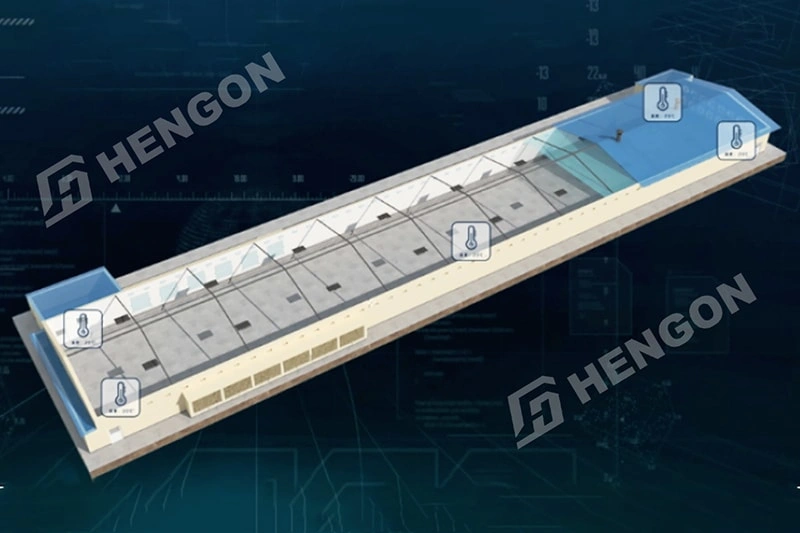

1. Intelligent Environmental Control Systems

Automated systems can monitor and adjust: temperature, humidity, wind speed, negative pressure, cooling pad operation, and fan stages. Continuous stability = consistent production.

2. Energy-Saving System Design

Long-term operating cost is the key concern for global poultry farms. Energy-efficient design includes:

- High-efficiency fans

- High R-value insulation materials

- Optimized inlet distribution

- Zonal ventilation and cooling

3. Standardized Management Enhances Productivity

Automation reduces human error and ensures consistent performance, improving growth rate, feed conversion rate, flock health, and production stability.

Conclusion: The Five Factors That Define a Modern, Efficient Poultry House

Building a modern poultry house is far more than assembling a simple structure. It requires precise control over geometry, airtightness, ventilation, cooling, and smart automation. With HENGON’s expertise in steel-structure poultry houses and environmental control systems, clients can achieve:

- Higher production performance

- Lower energy cost

- Reduced mortality

- Stronger return on investment

- Stable year-round output

Controlled environment + Scientific structure + High-efficiency ventilation = High-performance production.