1. Introduction

Structural steel and light gauge steel are two of the most widely used materials in modern construction. While they may appear similar, their production methods, applications, fastening systems, and performance characteristics differ significantly.

Understanding these differences is essential for architects, engineers, and developers when choosing the right material for any project.

2. What Is Structural Steel?

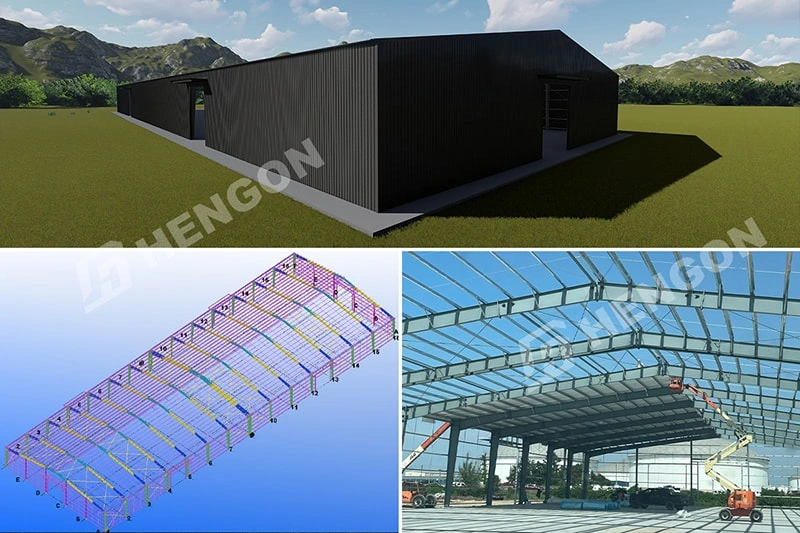

Structural steel refers to hot-rolled, heavy-duty steel sections used to form the primary skeleton of large structures.

These components provide exceptional strength and are commonly used in:

Warehouses and industrial workshops

Large-span buildings

High-rise structures

Bridges

Heavy-load platforms

Common types of structural steel used in construction include:

Universal Beams (UB)

Universal Columns (UC)

Tapered Flange Beams

Rectangular / Square Hollow Sections

Parallel Flange Channels

Tubular Hollow Sections

Structural steel is known for its high load-bearing capacity, long-term durability, and excellent performance in demanding environments.

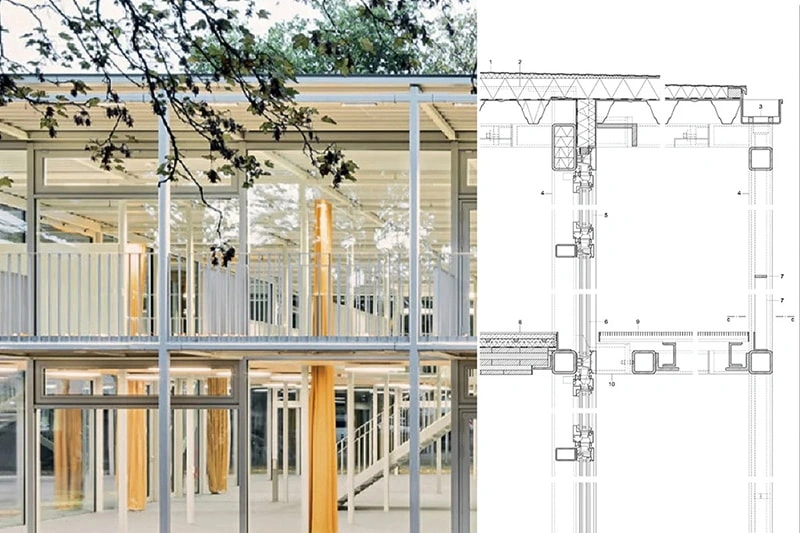

3. What Is Light Gauge Steel?

Light gauge steel—also called cold-formed or cold-rolled steel—is manufactured by bending thin steel sheets into shape at room temperature.

This production method increases precision, reduces weight, and allows efficient prefabrication.

Light gauge steel is commonly used for:

Residential buildings

Apartment units

Commercial interior partitions

Modular structures

Light commercial projects

It does not rot, warp, or attract pests, and is significantly lighter than structural steel and concrete.

4. Differences in Production Methods

Hot-rolled

Thick, heavy sections

Designed for high load-bearing structures

Light Gauge Steel

Cold-formed

Thin, precise sections

Ideal for prefabricated, lightweight applications

These manufacturing differences directly affect performance, installation, and project suitability.

5. Fastening & Installation Differences

Structural Steel typically requires:

Welding

Bolting

Riveting

These heavy fastening methods ensure stability in large and complex structures.

Light Gauge Steel uses:

Steel screws

Clip connections

Lightweight tools

This makes installation faster, cleaner, and more flexible, especially for tight construction schedules.

6. Advantages of Light Gauge Steel

Light gauge steel is widely appreciated for benefits such as:

Faster construction time

Reduced material weight

Eco-friendly with recyclable materials

Lower labor requirements

Cleaner and safer job sites

Highly customizable and precise fabrication

Can be constructed during winter

Lower overall installation cost

High resistance to moisture, pests, corrosion, and rot

Excellent fire ratings

These advantages make it an attractive choice for residential and modular construction.

7. Advantages of Structural Steel

Structural steel offers strong advantages for heavy-duty projects:

Exceptional load-bearing capacity

Superior strength for long spans

Highly durable in industrial environments

Suitable for multi-storey and large-scale buildings

Excellent seismic and wind resistance

Long service life with minimal maintenance

8. Applications in the Construction Sector

Structural Steel Applications

Industrial plants and workshops

Warehouses

Multi-floor buildings

Heavy-load bridges

High-wind or seismic zones

Light Gauge Steel Applications

Residential houses

Apartment buildings

Offices and commercial interiors

Prefabricated modular units

Temporary or relocatable structures

9. How to Choose Between the Two

The right type of steel depends on:

Building load requirements

Span and building height

Budget and construction timeline

Environmental conditions

Fire and safety requirements

Local building standards

Prefabrication needs

Projects requiring heavy loads, large spans, or high structural strength should choose structural steel.

Projects needing fast installation, lighter materials, and modular or residential solutions may benefit more from light gauge steel.

10. Conclusion

Both structural steel and light gauge steel play critical roles in modern construction.

While structural steel excels in strength and durability, light gauge steel offers precision, speed, and lightweight efficiency.

The best choice depends on your project’s unique requirements, objectives, and long-term performance expectations.