When building an Steel Structure Workshop in the Philippines, waterproofing is not just an optional design feature—it is a critical factor that determines the durability of the facility, the safety of production, and long-term operating costs.

With a tropical monsoon climate, the Philippines experiences year-round high temperatures, heavy rainfall, and frequent typhoons. Based on local climate conditions and extensive project experience, we have summarized five essential waterproofing recommendations to help you build durable, reliable Steel Structure Workshops in the Philippines.

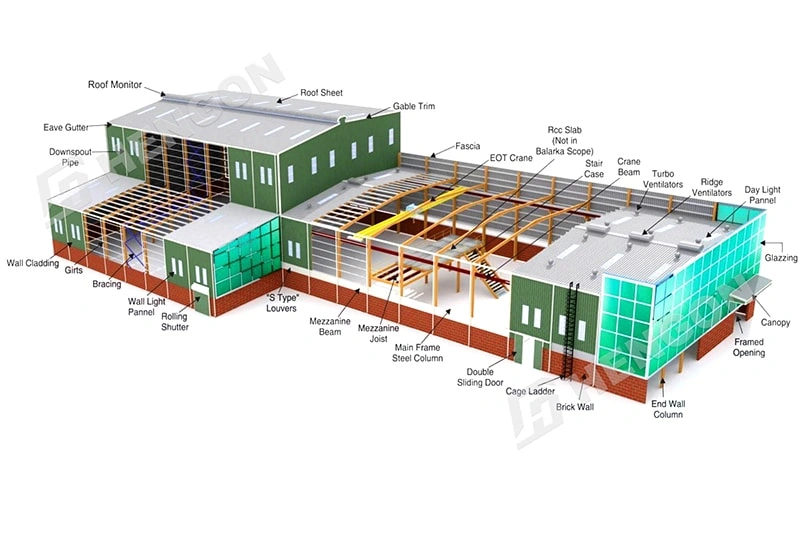

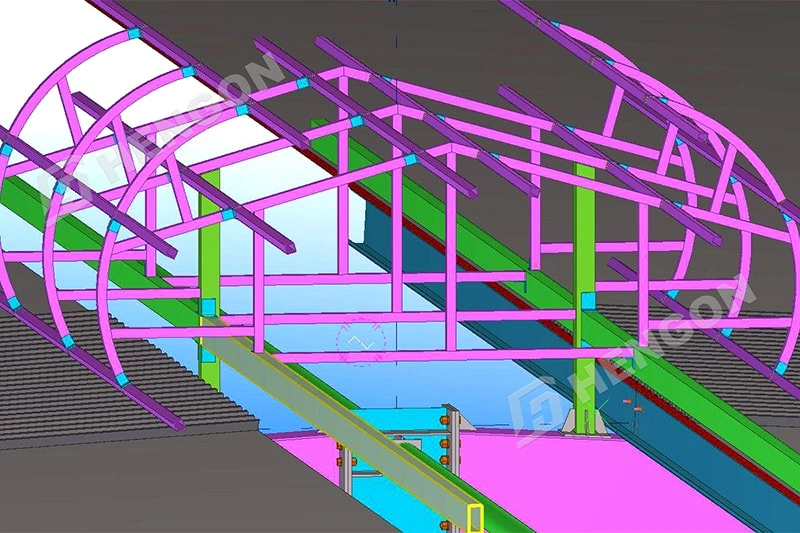

1. Roof Design: Use a Dual-Slope, Single-Ridge Structure

For Steel Structure Workshops in the Philippines, a gable roof with one main ridge is often the most reliable choice. Compared with complex multi-ridge or multi-span designs, the dual-slope roof minimizes the number of joints and intersection points where leaks typically occur.

The symmetrical slopes provide a clear drainage path on both sides of the ridge, allowing rainwater to flow quickly into gutters. This reduces the risk of water accumulation and leakage, while also improving wind resistance during typhoon season.

2. Wall Base: Build at least 1m Brick Wall to Block Groundwater

During the rainy season, soil in many areas becomes saturated, and some sites even face temporary flooding. If lightweight panels are used directly at ground level, moisture can seep into the interior, leading to mold, damp floors, and equipment damage.

A brick wall of at least 1 meter in height at the workshop base acts as a natural waterproof barrier. Dense masonry effectively blocks moisture from seeping upward, while also providing resistance against mud and debris during heavy rains. This design strengthens both the waterproofing and protective capacity of the walls.

3. Roof Accessories: Replace Skylights and Turbine Vents with Ridges Ventilator

Skylight strips and wind-driven turbine ventilators are common weak points in the Philippines’ hot, rainy, and storm-prone climate. Skylight joints are vulnerable to sealant failure, while turbine ventilators may allow rainwater to backflow under strong winds.

A better option is to install a ventilator ridge, which integrates ventilation and waterproofing in a single structure. Equipped with protective rain baffles and sealed joints,Ridge Ventilator ensure effective airflow inside the workshop while preventing water intrusion—offering durability with far less maintenance.

4. Gutter System: Opt for External Gutters, Not Internal

Internal gutters are hidden within the roof system. If clogged or poorly designed, they trap water inside the building envelope, leading to leaks, equipment damage, and costly downtime. Maintenance is also difficult because problems are often only noticed after leaks occur.

External gutters are installed outside the workshop walls, keeping the drainage path completely separate from the main structure. Even if blockages occur, they are easy to inspect and repair outdoors. External gutters are less affected by internal temperature differences, reducing deformation and extending waterproofing life.

5. Roof Slope: Maintain at Least a 15% Gradient

Rainfall in the Philippines can be intense and prolonged. A shallow roof slope allows water to linger, adding unnecessary load and increasing the risk of seepage.

Designing the roof with a slope of 15% or greater accelerates rainwater discharge, shortens the time water remains on the surface, and reduces the chance of leaks. A steeper slope also minimizes backflow at roof joints during typhoons. When combined with efficient external gutters, this creates a highly effective drainage system for Steel Structure Workshops.

Building Workshops That Endure in the Philippines

In the Philippines, waterproofing is not a secondary consideration but a fundamental requirement for Steel Structure Workshop construction. From roof design and wall materials to ventilation systems and gutter placement, each of these five strategies forms part of a complete waterproofing solution.

By applying these principles, businesses can build prefabricated steel workshops and industrial facilities that are durable, cost-efficient, and resilient to the Philippines’ challenging climate.